W. Edwards Deming’s funnel problem is one of statistics’ greatest hits. Deming was a noted statistician who took the statistical process control methods of Shewhart and expanded them into a holistic approach to manufacturing quality. Initially, his ideas were cooly received in the US and he ended up implementing them first in Japan. The success of the Japanese auto industry is due, in part, to its enthusiastic adoption of this total quality management (TQM) philosophy.

A core statistical component of TQM is the understanding of inherent random variability, and the disciplined and iterative use of designed experiments and data analysis to identify causes of variation that can be controlled, and reduce the uncontrolled random component.

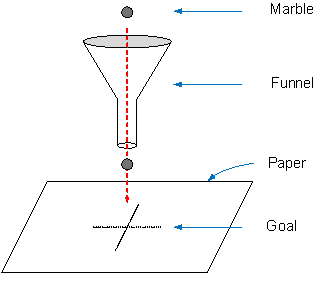

In his funnel experiment, Deming set up a funnel through which marbles were dropped. There was a target where the marbles were supposed to fall, and he tracked the locations where they actually fell. The subjects of the experiment were told the goal was to adjust the position of the funnel so that the marbles fell more precisely on target.

(source: https://squiretothegiants.files.wordpress.com/2015/07/funnel-experiment-set-up.png)

Statistically, the optimum procedure is to drop a number of marbles (i.e., a sample of sufficient size) through the funnel without adjusting the funnel, and find the average position where they fall. The deviation of the average position from the intended target is the magnitude and direction of the needed adjustment of the funnel position.

This, of course, is not natural human behavior. The natural reaction of people is to adjust the funnel immediately after a marble falls off target. Interestingly, the rule adjust after each marble produces the greatest overall variability – i.e. it makes the process more unstable. This corresponds to a number of counterproductive organizational behaviors that Deming identified:

-

Adjusting a process when a result is out of the range of its requirements

-

Making changes without the aid of control charts to monitor variation

-

Changing organization policy based on the latest employee satisfaction survey

-

Modifying the quota to reflect current output of the system

-

Using variances from previous budgets or expenditures to set new budgets

See https://deming.org/explore/the-funnel-experiment for more detail on the funnel experiment.